Acrylic stands have become ubiquitous in retail, exhibitions, events, and even home décor, thanks to their blend of clarity, strength, and design flexibility. Whether showcasing promotional materials at a point of sale, holding electronics at a trade show, or organizing cosmetics on a vanity, acrylic stands offer a professional and modern appearance. This article acrylic stand the world of acrylic stands: what they are, how they’re made, the many types available, key design considerations, common applications, and tips for choosing or customizing the perfect stand for your needs.

1. What Is an Acrylic Stand?

An acrylic stand is a holder or support structure made from acrylic (also known as polymethyl methacrylate, or PMMA). Acrylic is a transparent thermoplastic renowned for its glass-like clarity, lightweight acrylic standee, and excellent impact resistance—around ten times that of ordinary glass. Unlike glass, acrylic stands can be molded, cut, and polished into virtually any shape, making them ideal for displays requiring both aesthetics and durability.

Key properties of acrylic:

- Optical clarity: Transmits up to 92% of visible light, providing a crystal-clear appearance.

- Strength & safety: More impact-resistant than glass, less prone to shattering.

- Weather resistance: Performs well indoors and outdoors, with good UV stability when treated.

- Lightweight: Roughly half the weight of glass, reducing shipping costs and making handling easier.

- Workability: Easily cut, thermoformed, laser-etched, and bonded for custom shapes and finishes.

2. Common Types of Acrylic Stands

Acrylic stands come in a broad range of forms to suit different display needs. Below are some of the most popular types:

| Type | Description | Typical Use Cases |

|---|---|---|

| Tiered Risers | Multi-level platforms, often in 2–4 tiers. | Retail displays, product photography |

| Brochure & Literature | Slotted or pocketed holders sized for flyers, brochures, and catalogs. | Information desks, trade shows |

| Sign Holders | Single or double-sided sign frames, upright or countertop mounts. | Menus, pricing information, directional signage |

| Product Organizers | Compartments for cosmetics, office supplies, electronics accessories. | Cosmetics counters, office desks |

| Sheet Music Stands | Portable, angled supports for music scores, often with fold-flat designs. | Musicians, schools |

| Cup & Plate Racks | Slotted holders to display dishware in showrooms or as event décor. | Kitchens, events |

| Digital Device Stands | Angled holders sized for phones, tablets, e-readers. | Tech stores, home offices |

Each type can be produced in a variety of thicknesses (commonly 2–10 mm), colors (clear, tinted, or opaque), and finishes (glossy, frosted, or matte).

3. Manufacturing Processes

Turning raw acrylic sheets into finished stands involves several key processes:

- Cutting:

- Laser cutting offers precision and smooth edges, ideal for intricate shapes.

- CNC routing handles thicker sheets and produces beveled or sculpted edges.

- Forming & Bending:

- Thermoforming softens acrylic under heat, then bends it over molds to create curved forms (e.g., R-shaped brochure holders).

- Cold bending uses mechanical methods for gentle curves, without heat.

- Polishing & Edge Finishing:

- Flame polishing melts edge surfaces for a glossy finish.

- Buffing with abrasives yields matte or satin edges if desired.

- Bonding & Assembly:

- Solvent welding chemically fuses parts for invisible seams.

- UV-cured adhesives offer fast cure times and strong bonds, often used for colored acrylic.

- Surface Decoration:

- Screen printing adds logos, text, or color blocks.

- Digital UV printing allows high-resolution graphics directly onto the stand.

- Etching or engraving provides a tactile, frosted look for text or patterns.

4. Design Considerations

When selecting or specifying an acrylic stand, consider the following factors:

- Load & Stability:

- Ensure the stand’s thickness and footprint support the weight of the items it will hold.

- Non-slip pads or rubber feet can prevent sliding and protect surfaces.

- Viewing Angle & Ergonomics:

- Angle brochure or device holders between 15°–30° for comfortable viewing or access.

- Tiered displays should stagger each level by at least 30 mm for clear visibility.

- Portability & Storage:

- If the stand needs frequent transport, look for fold-flat or knock-down designs.

- Lightweight builds lower shipping costs and make setup easier.

- Aesthetic Matching:

- Coordinate acrylic color and finish with brand guidelines or décor motifs.

- Mix clear and tinted panels for visual interest or brand color accents.

- Durability & Environment:

- For outdoor or bright-light use, choose UV-stabilized acrylic to prevent yellowing.

- Consider scratch-resistant coatings if the stand will undergo heavy handling.

5. Applications Across Industries

Retail & Point of Sale

Acrylic stands elevate product displays—jewelry, cosmetics, electronics—by creating organized, clean layouts that draw customer attention. Their transparency lets products shine without visual clutter.

Trade Shows & Exhibitions

Lightweight yet sturdy, custom-printed acrylic sign holders and brochure racks build a polished booth presence. Branded backlit panels can also be integrated for high-impact visuals.

Hospitality & Events

Menus, seating charts, and informational signage benefit from acrylic’s durability and elegance. For weddings or corporate events, tinted acrylic can match color schemes.

Home & Office Organization

Desk organizers, makeup organizers, and book stands made of acrylic keep workspaces tidy while maintaining a minimalist aesthetic.

Museums & Galleries

Protective display cases and risers made of archival-quality acrylic offer both clarity and preservation for artifacts, artworks, and collectibles.

6. Customization & Branding

One of acrylic’s greatest strengths is its adaptability to branding and custom design:

- Logo Integration: Screen-print or UV-print your logo directly onto the stand’s front panel.

- Color Blocking: Use colored acrylic layers or inlays to echo brand palettes.

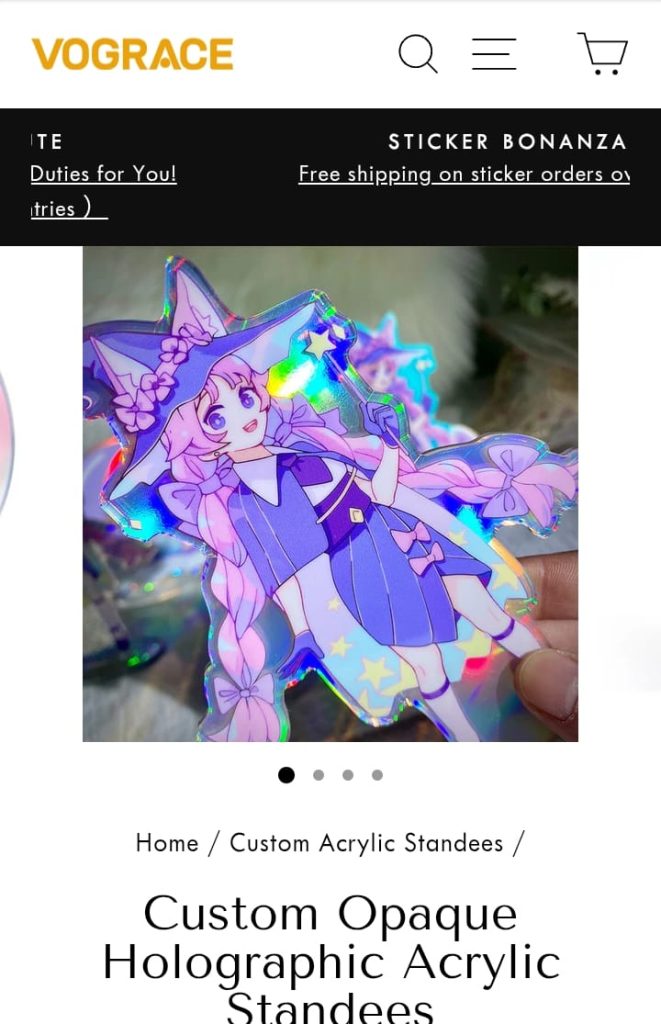

- Unique Shapes: Laser-cut silhouettes or die-cut shapes for thematic displays (e.g., product outline).

- Interactive Elements: Incorporate LED edge lighting or modular, interlocking pieces for dynamic exhibits.

Many manufacturers offer prototyping services—often via CNC or 3D printing—to refine designs before committing to mass production.

7. Maintenance & Care

To keep acrylic stands looking pristine:

- Cleaning: Use a soft microfiber cloth with a mild, non-abrasive soap solution.

- Avoid Scratches: Never use window cleaners containing ammonia or abrasive pads.

- Polishing Small Scratches: Fine acrylic polish or “scratch remover” kits can restore clarity to minor scuffs.

- Storage: Store flat or upright in a dry, cool place to prevent warping.

8. Buying Guide: What to Look For

- Supplier Expertise: Choose vendors with in-house fabrication and finishing capabilities to ensure quality control.

- Minimum Order Quantities (MOQs): Some custom colors or cuts may require higher MOQs—confirm before design finalization.

- Lead Times: Laser-cut orders typically ship in 1–2 weeks; thermoformed or highly customized items may take longer.

- Samples & Prototypes: Request a small sample piece or prototype mock-up to verify color match, clarity, and fit.

- Certifications: If you require food-safe or archival-quality acrylic, ensure the material meets relevant standards (e.g., FDA, ISO).

9. Conclusion

Acrylic stands seamlessly marry function with modern design, making them indispensable tools for retailers, event planners, exhibitors, and organizers. Their combination of clarity, durability, and design versatility ensures that products and information are showcased to their fullest potential. By understanding the types available, manufacturing processes, and design considerations—and by selecting a reliable supplier—you can elevate your displays and brand presentation with elegant acrylic solutions. Whether you need a simple brochure rack or a fully custom illuminated exhibit, acrylic stands offer the flexibility to bring your vision to life.